ISO 45001:2018 Occupational health and safety management systems

Occupational health and safety in Nepal is a critical aspect of ensuring the well-being and protection of the country's workforce. Nepal, with its diverse range of industries and work environments, recognizes the importance of establishing and maintaining effective occupational health and safety practices. Here are some key points to understand about occupational health and safety in Nepal:

Legal Framework: Nepal has established legal

frameworks and regulations to address occupational health and safety concerns.

The Labor Act, 2074 (2017) and the Occupational Health and Safety Regulation,

2075 (2018) provide the legal foundation for ensuring workplace safety. These

regulations outline the responsibilities of employers, workers, and government

authorities in promoting and enforcing occupational health and safety

standards.

Occupational

Hazards: Nepal's workforce faces various occupational hazards across

different sectors. Industries such as construction, manufacturing, agriculture,

and mining pose risks related to falls, physical injuries, exposure to harmful

substances, ergonomic issues, and more. It is crucial for organizations to

identify and mitigate these hazards to protect the health and safety of their

employees.

Challenges: Nepal

faces specific challenges in ensuring occupational health and safety. Limited

awareness and knowledge about safety practices, inadequate resources, and

infrastructural constraints pose challenges to implementing effective safety

measures. Additionally, the informal sector and small and medium-sized

enterprises (SMEs) often lack the necessary resources and expertise to address

occupational health and safety adequately.

Role of Government

Authorities: The Department of Labor and Occupational Safety and

Health Council under the Ministry of Labor, Employment and Social Security are

responsible for enforcing occupational health and safety regulations in Nepal.

These authorities conduct inspections, provide guidance, and monitor compliance

to ensure that workplaces adhere to safety standards

Importance of

Training and Awareness: Training and awareness programs play a crucial role

in improving occupational health and safety practices in Nepal. Organizations,

government agencies, and NGOs conduct training sessions, workshops, and

campaigns to educate workers and employers about potential hazards, safety

procedures, and preventive measures. Building awareness and knowledge empowers

individuals to actively contribute to maintaining a safe working environment

Collaboration and

Support: Collaboration between government authorities, industry

associations, and organizations is essential for promoting occupational health

and safety in Nepal. Sharing best practices, knowledge, and resources can

enhance the overall safety culture in workplaces. Engaging with international

organizations, such as the International Labour Organization (ILO), can also

provide valuable guidance and support in improving occupational health and

safety standards.

Continuous

Improvement: Continuous improvement is crucial in the field of

occupational health and safety. Regular evaluation of safety policies,

procedures, and risk assessments helps identify areas for improvement.

Encouraging feedback from employees, conducting incident investigations, and

implementing corrective actions contribute to a proactive safety culture and

ensure ongoing enhancement of occupational health and safety practices.

Ensuring occupational health and safety in

Nepal requires a collaborative effort between government authorities,

organizations, and workers. By adhering to legal regulations, raising

awareness, and implementing effective safety measures, Nepal can create safer

work environments and protect the well-being of its workforce. Prioritizing

occupational health and safety ultimately leads to improved productivity,

reduced workplace incidents, and a healthier workforce for the sustainable

development of the nation.

Occupational Health and Safety in Nepal

Occupational health and safety in Nepal is a critical aspect

of ensuring the well-being and protection of the country's workforce. Nepal,

with its diverse range of industries and work environments, recognizes the

importance of establishing and maintaining effective occupational health and

safety practices. Here are some key points to understand about occupational

health and safety in Nepal:

- Legal

Framework: Nepal has established legal frameworks and regulations to

address occupational health and safety concerns. The Labor Act, 2074

(2017) and the Occupational Health and Safety Regulation, 2075 (2018)

provide the legal foundation for ensuring workplace safety. These

regulations outline the responsibilities of employers, workers, and

government authorities in promoting and enforcing occupational health and

safety standards.

- Occupational

Hazards: Nepal's workforce faces various occupational hazards across

different sectors. Industries such as construction, manufacturing,

agriculture, and mining pose risks related to falls, physical injuries,

exposure to harmful substances, ergonomic issues, and more. It is crucial

for organizations to identify and mitigate these hazards to protect the

health and safety of their employees.

- Challenges:

Nepal faces specific challenges in ensuring occupational health and

safety. Limited awareness and knowledge about safety practices, inadequate

resources, and infrastructural constraints pose challenges to implementing

effective safety measures. Additionally, the informal sector and small and

medium-sized enterprises (SMEs) often lack the necessary resources and

expertise to address occupational health and safety adequately.

- Role

of Government Authorities: The Department of Labor and Occupational Safety

and Health Council under the Ministry of Labor, Employment and Social

Security are responsible for enforcing occupational health and safety

regulations in Nepal. These authorities conduct inspections, provide

guidance, and monitor compliance to ensure that workplaces adhere to

safety standards.

- Importance

of Training and Awareness: Training and awareness programs play a crucial

role in improving occupational health and safety practices in Nepal.

Organizations, government agencies, and NGOs conduct training sessions,

workshops, and campaigns to educate workers and employers about potential

hazards, safety procedures, and preventive measures. Building awareness

and knowledge empowers individuals to actively contribute to maintaining a

safe working environment.

- Collaboration

and Support: Collaboration between government authorities, industry

associations, and organizations is essential for promoting occupational

health and safety in Nepal. Sharing best practices, knowledge, and

resources can enhance the overall safety culture in workplaces. Engaging

with international organizations, such as the International Labour

Organization (ILO), can also provide valuable guidance and support in

improving occupational health and safety standards.

- Continuous

Improvement: Continuous improvement is crucial in the field of

occupational health and safety. Regular evaluation of safety policies,

procedures, and risk assessments helps identify areas for improvement.

Encouraging feedback from employees, conducting incident investigations,

and implementing corrective actions contribute to a proactive safety

culture and ensure ongoing enhancement of occupational health and safety

practices.

Occupational health and safety laws in Nepal

Occupational health and safety laws in Nepal are designed to protect the well-being and safety of workers across various industries. These laws outline the rights and responsibilities of employers, employees, and government authorities in ensuring a safe working environment. Here are key points regarding occupational health and safety laws in Nepal:

- Labor Act, 2074 (2017): The Labor Act, 2074, is the primary legislation governing labor issues in Nepal, including occupational health and safety. It covers both public and private sector workers and sets out the legal framework for ensuring workplace safety.

- Occupational Health and Safety Regulation, 2075 (2018): The Occupational Health and Safety Regulation, 2075, is a specific set of regulations issued under the Labor Act. These regulations provide detailed guidelines and requirements for employers and employees to ensure oOccupational Health and Safety Committeeccupational health and safety in the workplace.

- Under the law, employers are required to establish an Occupational Health and Safety Committee in workplaces with a certain number of employees. This committee comprises representatives from management and workers and is responsible for monitoring and promoting occupational health and safety practices.

- Duties and Responsibilities of Employers: Employers have several obligations under the occupational health and safety laws in Nepal, including:

- Providing a safe and healthy working environment for employees.

- Identifying and assessing workplace hazards and implementing measures to control and mitigate risks.

- Developing and implementing occupational health and safety policies, procedures, and programs.

- Providing appropriate training and information to employees regarding health and safety practices.

- Establishing emergency response plans and procedures.

- Maintaining records of accidents, injuries, and illnesses and reporting them to the relevant authorities.

- Duties and Rights of Employees: Employees also have certain rights and responsibilities concerning occupational health and safety, including:

- Complying

with occupational health and safety policies and procedures.

- Reporting

any workplace hazards, accidents, or near misses to the employer or the

Occupational Health and Safety Committee.

- Participating

in occupational health and safety training and programs.

- Refusing work that poses an immediate and serious danger to their health and safety.

- Inspections and Enforcement: Government authorities, such as the Department of Labor and Occupational Safety and Health Council, conduct regular inspections to ensure compliance with occupational health and safety laws. They have the authority to issue warnings, fines, or take legal actions against employers who violate safety regulations

- Penalties and Legal Consequences: Non-compliance with occupational health and safety laws can result in penalties, fines, or legal actions against the employer. In cases of severe violations or negligence leading to serious injuries or fatalities, criminal charges may be filed.

It is crucial for employers to be aware of and adhere to the

occupational health and safety laws in Nepal. By prioritizing workplace safety,

organizations can protect their employees' well-being, prevent accidents and

injuries, and contribute to a productive and healthy work environment. Regular

training, hazard assessments, and proactive safety measures are essential for

maintaining compliance and ensuring occupational health and safety in Nepalese

workplaces.

Why is ISO 45001:2018 Important?

ISO 45001:2018 is an important international standard for occupational health and safety management systems. It provides organizations with a framework to effectively manage occupational health and safety risks and promote a safe working environment. Here are key reasons why ISO 45001:2018 is important

:

- Employee Safety and Well-being: Implementing ISO 45001 demonstrates an organization's commitment to the safety and well-being of its employees. It helps identify and address potential hazards, reduce workplace accidents and injuries, and create a culture of safety. By prioritizing employee safety, organizations can protect their most valuable asset and enhance employee morale and satisfaction.

- Legal Compliance: ISO 45001 helps organizations comply with relevant legal and regulatory requirements related to occupational health and safety. It provides a systematic approach to identify and meet legal obligations, reducing the risk of non-compliance, penalties, and legal liabilities. Compliance with ISO 45001 demonstrates a commitment to fulfilling legal requirements and ensures a safer working environment.

- Improved Risk Management: ISO 45001 focuses on identifying and assessing occupational health and safety risks within an organization. By implementing effective risk management processes, organizations can proactively mitigate risks, prevent incidents, and minimize the potential for accidents, injuries, and illnesses. This systematic approach enhances overall risk management capabilities and safeguards the well-being of employees.

- Enhanced Productivity and Efficiency: A safe and healthy working environment contributes to increased productivity and efficiency. By implementing ISO 45001, organizations can reduce absenteeism, improve employee engagement and motivation, and create a positive work atmosphere. Employees feel valued and supported, leading to improved performance and productivity levels.

- Reputation

and Stakeholder Confidence: ISO 45001 certification enhances an

organization's reputation and instills confidence among stakeholders,

including employees, customers, suppliers, and investors. It demonstrates

a commitment to responsible business practices, employee welfare, and

sustainable operations. ISO 45001 certification can also provide a

competitive advantage by differentiating the organization from its peers

and attracting stakeholders who prioritize occupational health and safety.

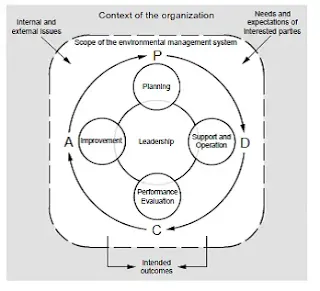

- Continuous

Improvement: ISO 45001 follows the Plan-Do-Check-Act (PDCA) cycle,

promoting a culture of continuous improvement. Organizations regularly

assess their occupational health and safety performance, identify areas

for improvement, and take corrective actions. This iterative process helps

organizations stay proactive in addressing emerging risks, enhancing

safety measures, and continually improving their occupational health and

safety management systems.

- International

Recognition: ISO 45001 is an internationally recognized standard.

Achieving certification demonstrates conformity to globally accepted

practices in occupational health and safety. This recognition can be

beneficial for organizations operating internationally, as it facilitates

compliance with local regulations and provides a consistent framework for

managing health and safety across multiple locations.

ISO 45001:2018 is important for organizations as

it prioritizes employee safety, ensures legal compliance, improves risk

management, enhances productivity, builds reputation and stakeholder

confidence, fosters continuous improvement, and provides international

recognition. By implementing ISO 45001, organizations can create safer work

environments, protect employees, and achieve sustainable business success.

Occupational Health and Safety specialist

An Occupational Health and Safety (OHS) specialist, also

known as an OHS professional or safety specialist, is an individual with

specialized knowledge and expertise in occupational health and safety practices

and regulations. Their primary role is to ensure the health, safety, and

well-being of employees in the workplace. Here is an overview of the

responsibilities and skills of an OHS specialist:

Responsibilities of an Occupational Health and Safety Specialist:

- Risk

Assessment: Conducting thorough risk assessments to identify potential

hazards and risks in the workplace. This includes assessing physical,

chemical, biological, and ergonomic factors that may pose a threat to

employee health and safety.

- Compliance:

Ensuring compliance with relevant occupational health and safety

regulations, standards, and guidelines. This involves staying up to date

with changes in legislation and ensuring that organizational policies and

practices align with legal requirements.

- Policy

Development: Developing and implementing occupational health and safety

policies, procedures, and programs within the organization. These policies

aim to prevent accidents, injuries, and illnesses and promote a safe

working environment.

- Training

and Education: Providing training and education to employees on

occupational health and safety practices. This includes conducting safety

inductions, organizing training sessions, and raising awareness about

potential risks and preventive measures.

- Incident

Investigation: Investigating workplace incidents, accidents, or near

misses to determine their root causes. The goal is to identify areas for

improvement and develop strategies to prevent similar incidents in the

future.

- Emergency

Preparedness: Developing emergency response plans and procedures to

effectively handle emergencies such as fires, natural disasters, or

chemical spills. This includes conducting drills, ensuring proper signage,

and maintaining emergency equipment.

- Safety

Inspections and Audits: Conducting regular inspections and audits of the

workplace to identify potential hazards, assess safety measures, and

ensure compliance with occupational health and safety standards.

- Collaboration

and Communication: Collaborating with management, employees, and relevant

stakeholders to promote a culture of safety. This includes communicating

safety policies, addressing employee concerns, and fostering a proactive

approach to occupational health and safety.

Skills of an Occupational Health and Safety Specialist:

- Knowledge

of OHS Regulations: In-depth understanding of local and international

occupational health and safety regulations, standards, and guidelines.

- Risk

Assessment and Management: Proficiency in conducting risk assessments,

identifying hazards, and implementing effective risk management

strategies.

- Communication:

Excellent communication skills to effectively communicate safety policies,

provide training, and promote safety awareness among employees.

- Problem-Solving:

Strong problem-solving skills to identify safety issues, investigate

incidents, and develop appropriate solutions.

- Attention

to Detail: Keen attention to detail to identify potential hazards and

ensure compliance with safety standards.

- Analytical

Skills: Ability to analyze data and interpret trends to identify patterns

and areas for improvement in occupational health and safety practices.

- Teamwork

and Collaboration: Collaborative approach to work with various

stakeholders, including employees, management, and external agencies, to

promote a safe working environment.

- Continuous

Learning: Willingness to stay updated with the latest developments in

occupational health and safety regulations, technologies, and best

practices.

Occupational Health and Safety specialists play a crucial

role in promoting a safe and healthy work environment. Their expertise and

dedication contribute to preventing accidents, protecting employee well-being,

and ensuring compliance with occupational health and safety standards.

What are the Key Elements of ISO 45001:2018?

The key elements of ISO 45001:2018, the international

standard for Occupational Health and Safety Management Systems (OHSMS), outline

the requirements and components that organizations need to consider when

implementing an effective occupational health and safety management system. The

following are the key elements of ISO 45001:2018:

- Context

of the Organization: This element requires organizations to identify the

internal and external factors that can impact their occupational health

and safety management system. It includes understanding the organization's

context, identifying interested parties and their needs, and determining

the scope of the OHSMS.

- Leadership

and Worker Participation: This element emphasizes the role of top

management in demonstrating leadership and commitment to occupational

health and safety. It requires establishing a clear occupational health

and safety policy, defining roles and responsibilities, and actively

involving workers in decision-making processes related to health and

safety.

- Planning:

The planning element focuses on systematically addressing risks and

opportunities related to occupational health and safety. It involves

conducting a thorough assessment of hazards, assessing legal and other

requirements, setting objectives, and developing action plans to achieve

those objectives.

- Support :The support element highlights the need for resources and support systems

to effectively implement and maintain the OHSMS. It covers areas such as

competence and training, communication, documentation, and the provision

of necessary resources for occupational health and safety.

- Operation:

This element deals with the execution of the planned activities to achieve

the defined occupational health and safety objectives. It includes

implementing controls and processes to manage hazards, emergency

preparedness and response, and ensuring effective operational controls.

- Performance

Evaluation: The performance evaluation element focuses on monitoring and

measuring the effectiveness of the occupational health and safety

management system. It requires organizations to establish performance

indicators, conduct internal audits, evaluate compliance, and monitor the

achievement of objectives.

- Improvement:

The improvement element emphasizes the need for continuous improvement in

occupational health and safety performance. It involves taking corrective

actions to address nonconformities, learning from incidents and accidents,

implementing preventive measures, and continually enhancing the OHSMS.

- Management

Review: This element requires top management to periodically review the

performance of the OHSMS. It involves evaluating the effectiveness of the

system, considering opportunities for improvement, and making necessary

adjustments to achieve the desired outcomes.

These key elements form the foundation of ISO 45001:2018 and

provide a systematic framework for organizations to manage occupational health

and safety risks, protect workers' well-being, and continually improve their

occupational health and safety performance. By addressing these elements,

organizations can create a safer work environment, reduce accidents and

injuries, and enhance overall health and safety management.

How Can Organizations Achieve Compliance with ISO 45001:2018?

Achieving compliance with ISO 45001:2018, the international

standard for Occupational Health and Safety Management Systems (OHSMS),

involves a systematic approach to implementing and maintaining the requirements

of the standard. Here are the steps organizations can take to achieve

compliance with ISO 45001:2018:

- Understand

the Standard: Familiarize yourself with the requirements of ISO 45001:2018

by studying the standard in detail. Understand the key elements, clauses,

and terminology used in the standard to gain a comprehensive understanding

of its requirements.

- Conduct

a Gap Analysis: Perform a gap analysis to identify the existing

occupational health and safety practices and systems within your

organization and compare them against the requirements of ISO 45001:2018.

This will help identify areas where your organization is already compliant

and areas that require improvement or additional measures.

- Develop

an Implementation Plan: Based on the findings of the gap analysis, develop

a detailed implementation plan that outlines the steps, timelines, and

resources required to achieve compliance with ISO 45001:2018. Assign

responsibilities and establish clear objectives for each stage of the

implementation process.

- Establish

Leadership Commitment: Obtain commitment and support from top management

to prioritize occupational health and safety within the organization.

Ensure that leadership is actively involved in the implementation process,

sets clear objectives, and allocates resources to support the OHSMS.

- Engage

Employees: Involve employees at all levels in the implementation of ISO

45001:2018. Create awareness about the importance of occupational health

and safety, provide training and education on the requirements of the

standard, and encourage active participation and feedback from employees.

- Develop

and Implement Policies and Procedures: Develop comprehensive occupational

health and safety policies and procedures that align with the requirements

of ISO 45001:2018. Ensure that these policies address hazards, risk

assessment and management, emergency preparedness, incident reporting, and

other relevant areas.

- Establish

Documentation and Records: Develop a robust documentation system to record

and manage occupational health and safety-related information, including

policies, procedures, risk assessments, training records, incident

reports, and audit findings. Ensure that these documents are accessible,

up to date, and easily retrievable.

- Implement

Controls and Processes: Implement controls and processes to manage occupational

health and safety risks within the organization. This may include

establishing hazard identification and risk assessment processes,

implementing controls to mitigate risks, and developing procedures for

incident reporting and investigation.

- Conduct

Internal Audits: Regularly conduct internal audits to assess the

effectiveness of the implemented occupational health and safety management

system. This will help identify non-conformities, areas for improvement,

and ensure ongoing compliance with ISO 45001:2018.

- Continual

Improvement: Promote a culture of continual improvement by analyzing data,

monitoring performance indicators, and implementing corrective and

preventive actions. Regularly review the effectiveness of the OHSMS, learn

from incidents and near misses, and make necessary adjustments to enhance

occupational health and safety performance.

- Seek

Certification (Optional): Organizations can choose to seek certification

from a recognized certification body to validate their compliance with ISO

45001:2018. The certification process involves an assessment by an

external auditor who verifies that the organization's OHSMS meets the

requirements of the standard.

By following these steps, organizations can systematically

implement the requirements of ISO 45001:2018 and achieve compliance with the

standard. It is important to note that compliance is an ongoing process, and

organizations should continually monitor, evaluate, and improve their

occupational health and safety management systems to ensure the well-being of

employees and compliance with the standard's requirements.

Benefits of ISO 45001:2018

ISO 45001:2018, the international standard for Occupational

Health and Safety Management Systems (OHSMS), offers several benefits to

organizations that implement and adhere to its requirements. Here are some key

benefits of ISO 45001:2018:

- Enhanced

Occupational Health and Safety Performance: ISO 45001 helps organizations

improve their occupational health and safety performance by providing a

systematic framework for identifying, assessing, and managing risks and

hazards in the workplace. It promotes a proactive approach to safety,

reducing the likelihood of accidents, injuries, and work-related

illnesses.

- Legal

and Regulatory Compliance: Implementing ISO 45001 helps organizations

comply with applicable occupational health and safety laws, regulations,

and standards. It ensures that the organization is aware of its legal

obligations and takes necessary measures to meet those requirements, thereby

reducing the risk of non-compliance and associated penalties.

- Improved

Employee Safety and Well-being: ISO 45001 places a strong emphasis on

employee safety and well-being. By implementing effective controls and

measures to mitigate risks, organizations create a safer work environment

for their employees. This leads to a reduction in accidents, injuries, and

illnesses, fostering a positive workplace culture and enhancing employee

morale.

- Increased

Employee Engagement and Participation: ISO 45001 encourages active

employee involvement in the development, implementation, and improvement

of the occupational health and safety management system. It promotes open

communication, encourages reporting of hazards and incidents, and seeks

employee feedback, thereby fostering a sense of ownership and engagement

among employees.

- Reduced

Costs and Increased Efficiency: Effective management of occupational

health and safety risks can result in cost savings for organizations. By

preventing accidents and injuries, organizations can reduce costs

associated with medical treatment, compensation claims, downtime, and

production disruptions. Additionally, improved efficiency in processes and

operations can lead to overall cost reduction.

- Enhanced

Reputation and Stakeholder Confidence: Achieving ISO 45001 certification

demonstrates an organization's commitment to ensuring the health and

safety of its employees. It enhances the organization's reputation as a

responsible and reliable business partner. Customers, stakeholders, and

the community at large gain confidence in the organization's ability to

operate in a safe and socially responsible manner.

- Improved

Risk Management: ISO 45001 promotes a systematic approach to identifying,

assessing, and managing occupational health and safety risks. It helps

organizations establish effective risk management processes, ensuring that

potential hazards are identified and appropriate controls are implemented.

This leads to a proactive approach to risk prevention and mitigation.

- Facilitates

Continuous Improvement: ISO 45001 encourages organizations to adopt a

culture of continuous improvement in occupational health and safety

performance. Through regular audits, evaluations, and reviews,

organizations can identify areas for improvement, implement corrective

actions, and enhance their safety management systems over time.

- Competitive

Advantage: ISO 45001 certification can provide a competitive advantage in

the marketplace. Many customers, especially in industries where safety is

a critical concern, prefer to work with certified organizations. ISO 45001

certification can open doors to new business opportunities and enable

organizations to differentiate themselves from competitors.

ISO 45001:2018, organizations can reap these

benefits and create a safer, healthier work environment for their employees

while meeting legal obligations, improving operational efficiency, and

enhancing their reputation in the marketplace.

key performance indicators for occupational health and safety

Key Performance Indicators (KPIs) are used to measure the

performance and effectiveness of occupational health and safety (OHS) programs

within organizations. These indicators help monitor progress, identify areas

for improvement, and ensure that health and safety objectives are being

achieved. While the specific KPIs may vary depending on the organization and

industry, here are some commonly used KPIs for occupational health and safety:

- Lost

Time Injury Frequency Rate (LTIFR): LTIFR measures the number of lost time

injuries (injuries that result in a person being unable to work for a

certain period) per million hours worked. It provides an indication of the

overall safety performance and the rate of injuries resulting in lost work

time.

- Total

Recordable Injury Frequency Rate (TRIFR): TRIFR measures the number of

total recordable injuries (including lost time injuries, medical treatment

injuries, and restricted work injuries) per million hours worked. It

provides a broader view of the overall injury rate within the

organization.

- Severity

Rate: Severity rate measures the severity of injuries and illnesses by

calculating the number of lost workdays per 200,000 hours worked. It

focuses on the impact and duration of injuries and illnesses on the

affected workers.

- Near

Miss Reporting Rate: Near miss reporting rate measures the number of

reported near misses (incidents that could have resulted in injury or

illness but did not) per period. It reflects the organization's proactive

approach to identifying and addressing potential hazards before they cause

harm.

- Compliance

Rate: Compliance rate measures the percentage of compliance with

occupational health and safety policies, procedures, and regulatory

requirements. It reflects the organization's adherence to established

safety protocols and practices.

- Safety

Training Completion Rate: Safety training completion rate measures the

percentage of employees who have completed the required occupational

health and safety training. It indicates the level of employee engagement

and commitment to safety education and awareness.

- Hazard

Identification and Resolution Rate: This KPI measures the rate at which

hazards are identified, reported, and resolved within the organization. It

reflects the effectiveness of hazard identification systems and the

organization's responsiveness in addressing identified risks.

- Safety

Culture Index: The safety culture index measures the perceptions and

attitudes of employees toward occupational health and safety within the

organization. It is usually assessed through surveys or questionnaires and

provides insight into the overall safety culture and employee engagement

in safety practices.

- Emergency

Response Time: Emergency response time measures the time taken to respond

to emergencies or incidents within the workplace. It reflects the

organization's preparedness and efficiency in addressing emergency

situations.

- Safety

Audit Findings Closure Rate: This KPI measures the rate at which safety

audit findings and recommendations are closed or resolved. It indicates

the organization's commitment to addressing identified gaps and

implementing corrective actions.

It's important to note that organizations should select KPIs

that align with their specific goals, objectives, and industry requirements.

These indicators should be regularly monitored, analyzed, and used to drive

continuous improvement in occupational health and safety performance.

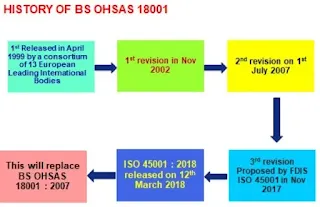

What does ISO 45001:2018 replace?

ISO 45001:2018 replaces the previous international standard for occupational health and safety management, OHSAS 18001:2007. OHSAS 18001 (Occupational Health and Safety Assessment Series) was a widely recognized standard developed by a consortium of leading certification bodies and national standards organizations.

ISO 45001:2018 was developed by the International

Organization for Standardization (ISO) and is designed to provide a more

comprehensive and globally applicable framework for managing occupational

health and safety. It aligns with other ISO management system standards, such

as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management),

making it easier for organizations to integrate their management systems.

The transition from OHSAS 18001 to ISO 45001 brings several

improvements and benefits, including:

- Alignment

with HLS Structure: ISO 45001 follows the High-Level Structure (HLS)

framework, which is common to all new ISO management system standards.

This allows for easier integration with other management systems and

facilitates a consistent approach across different disciplines.

- Enhanced

Risk-Based Approach: ISO 45001 places a greater emphasis on a risk-based

approach to occupational health and safety management. It requires

organizations to identify and assess risks, determine appropriate controls,

and monitor their effectiveness to prevent work-related injuries,

illnesses, and incidents.

- Leadership

Engagement: ISO 45001 emphasizes the role of leadership in driving

occupational health and safety performance. It requires top management to

demonstrate leadership commitment, establish policies, and allocate

resources to support the effective implementation of the management

system.

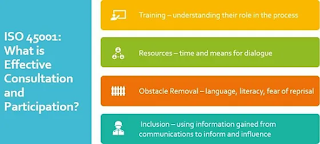

- Worker

Involvement: ISO 45001 promotes worker participation and consultation in

the development, implementation, and improvement of the management system.

It recognizes the valuable insights and contributions of workers in

identifying hazards, assessing risks, and implementing control measures.

- Context

of the Organization: ISO 45001 requires organizations to consider the internal

and external factors that may impact their occupational health and safety

performance. This includes understanding the needs and expectations of

interested parties, complying with legal requirements, and addressing

relevant social, economic, and environmental conditions.

- Continuous

Improvement: ISO 45001 emphasizes the importance of continual improvement

in occupational health and safety performance. It requires organizations

to establish processes for monitoring, measuring, and evaluating their performance,

and taking actions to address nonconformities and improve effectiveness.

- Documentation

Requirements: ISO 45001 introduces streamlined documentation requirements,

focusing on the necessary information to support the effective operation

of the management system. This reduces unnecessary paperwork and allows

organizations to focus on key processes and outcomes.

By replacing OHSAS 18001 with ISO 45001, organizations can

benefit from a more robust and internationally recognized standard that

provides a systematic and proactive approach to managing occupational health

and safety. The transition allows organizations to align their management

systems with current best practices and demonstrate their commitment to the

well-being of their workers.

what is difference between ISO 45001 and OHSAS 18001?

ISO 45001 and OHSAS 18001 are two different standards for occupational health and safety management systems. Here are some key differences between ISO 45001 and OHSAS 18001:

|

Aspect |

ISO

45001 |

OHSAS

18001 |

|

Publication

Date |

Published

in March 2018. |

Originally

published in 1999, with a revision in 2007. |

|

Origin |

Developed

by the International Organization for Standardization (ISO). |

Developed

by a selection of international standards bodies and certification bodies. |

|

Framework |

Based

on the Annex SL framework, common to all new and revised ISO standards. |

Has its

own unique framework, not aligned with Annex SL. |

|

Structure |

Uses a

high-level structure with 10 clauses. |

Uses a

different structure with fewer clauses. |

|

Worker

Participation |

Emphasizes

the participation and consultation of non-managerial workers in the OHS

management system. |

Less

emphasis on worker participation compared to ISO 45001. |

|

Risk

Management |

Focuses

on proactive risk prevention and opportunities alongside risk assessment. |

Focuses

mainly on risk assessment. |

|

Leadership |

Strong

emphasis on leadership and management commitment. Requires integration into

business processes. |

Focuses

on health & safety policy with less emphasis on leadership integration. |

|

Context

of Organization |

Requires

the organization to consider both external and internal factors that affect

its OH&S management system. |

Doesn't

explicitly address external factors or opportunities. |

|

Supply

Chain |

Addresses

risks and opportunities in the supply chain and outsourced processes. |

Has

less emphasis on supply chain management. |

|

Objective |

Aims to

improve the overall health and safety system, reducing work-related injuries

and ill-health. |

Aims

primarily at controlling hazards and reducing potential for accidents. |

Overall, ISO 45001 provides a more robust and comprehensive

framework for managing occupational health and safety compared to OHSAS 18001.

It aligns with other ISO management system standards, focuses on risk

management, emphasizes leadership and worker involvement, and encourages

continual improvement. Organizations transitioning from OHSAS 18001 to ISO

45001 can benefit from the enhanced requirements and alignment with

international best practices.

Auditors view on ISO 45001:2018

Here are some key aspects that auditors may consider:

- Comprehensive

and Risk-Based Approach: Auditors generally appreciate the risk-based

approach of ISO 45001:2018, as it emphasizes proactive identification and

management of occupational health and safety risks. They look for evidence

that organizations have conducted thorough hazard identification and risk

assessment processes, implemented appropriate control measures, and

regularly reviewed their effectiveness.

- Leadership

and Management Commitment: Auditors focus on assessing the commitment of

top management to occupational health and safety. They evaluate whether

leaders have established a clear policy, allocated resources, and

demonstrated active involvement in promoting a positive safety culture.

Auditors expect to see evidence of leadership engagement and communication

throughout the organization.

- Worker

Involvement and Participation: Auditors recognize the importance of worker

involvement and participation in achieving effective health and safety

management. They assess whether organizations have mechanisms in place to

engage workers in hazard identification, risk assessment, incident

reporting, and decision-making processes. Auditors look for evidence of

effective communication channels and documented worker participation

procedures.

- Compliance

with Legal and Regulatory Requirements: Auditors verify that organizations

have a systematic process for identifying and complying with relevant

occupational health and safety legal requirements. They assess whether

organizations maintain an up-to-date register of applicable laws and

regulations, monitor changes, and take necessary actions to ensure

compliance.

- Performance

Monitoring and Measurement: Auditors examine how organizations monitor and

measure their occupational health and safety performance. They review key

performance indicators, incident reporting mechanisms, and data analysis

processes to assess the effectiveness of performance monitoring. Auditors

also look for evidence of regular management review meetings and actions

taken to address performance gaps.

- Documentation

and Records: Auditors assess the adequacy and effectiveness of the

documented information and records related to the occupational health and

safety management system. They review policies, procedures, risk

assessments, training records, incident reports, and other relevant

documentation to ensure compliance with ISO 45001 requirements.

- Continuous

Improvement: Auditors focus on the organization's commitment to continual

improvement in occupational health and safety. They look for evidence of

corrective and preventive actions taken to address nonconformities,

incidents, and identified improvement opportunities. Auditors also assess

the effectiveness of the organization's processes for management review

and performance evaluation.

It's important to note that auditors play a critical role in

evaluating an organization's compliance with ISO 45001:2018. Their feedback and

recommendations can help organizations enhance their occupational health and

safety management systems, drive continuous improvement, and achieve

certification.

ISO 45001:2018 OHSMS Auditing

ISO 45001:2018 OHSMS auditing refers to the process of

assessing an organization's compliance with the requirements of the ISO 45001

standard for Occupational Health and Safety Management Systems (OHSMS).

Auditing plays a crucial role in evaluating the effectiveness of an

organization's OHSMS, identifying areas for improvement, and ensuring ongoing

compliance with the standard. Here are some key aspects related to ISO

45001:2018 OHSMS auditing:

- Purpose

of Auditing: The primary purpose of ISO 45001:2018 auditing is to verify

that an organization's OHSMS meets the requirements of the standard and is

effectively implemented. Auditing helps organizations identify gaps,

weaknesses, and non-conformities in their OHSMS, providing an opportunity

for corrective actions and continual improvement.

- Internal

and External Audits: ISO 45001:2018 OHSMS audits can be conducted internally

by trained personnel within the organization or externally by independent

certification bodies. Internal audits help organizations assess their own

OHSMS and prepare for external audits. External audits, conducted by

certified auditors, lead to the issuance of ISO 45001 certification if the

organization meets the standard's requirements.

- Audit

Planning: Before conducting an audit, auditors develop an audit plan that

outlines the scope, objectives, and methodologies for the audit. The plan

includes determining the audit criteria, selecting audit teams, scheduling

the audit activities, and identifying the necessary resources.

- Audit

Process: The audit process typically includes the following stages: a.

Opening Meeting: The audit begins with an opening meeting where the audit

objectives, scope, and procedures are communicated to the auditee (the

organization being audited). The audit team and auditee discuss the audit

schedule and any logistical arrangements. b. Document Review: Auditors

review the organization's OHSMS documentation, including policies,

procedures, risk assessments, incident reports, and records, to assess

compliance with ISO 45001:2018 requirements. c. On-site Inspection:

Auditors conduct on-site inspections, observing workplace conditions,

equipment, work practices, and employee interviews to evaluate the

implementation and effectiveness of the OHSMS. d. Interviews and

Discussions: Auditors interview personnel at various levels within the

organization to gather information, clarify processes, and assess

awareness and understanding of the OHSMS. e. Non-conformity

Identification: Auditors identify non-conformities, which are instances

where the organization's practices do not meet the requirements of ISO

45001:2018. Non-conformities may relate to gaps in procedures, inadequate

controls, or failure to meet legal or regulatory requirements. f.

Reporting and Follow-up: Auditors prepare an audit report that documents

their findings, including any non-conformities identified. The

organization then takes corrective actions to address the

non-conformities, and auditors may conduct follow-up audits to verify

their effectiveness.

- Auditor

Competence: ISO 45001:2018 audits should be conducted by competent

auditors who have the necessary knowledge, skills, and experience in OHSMS

and auditing techniques. Auditors should be impartial, independent, and

act in accordance with relevant auditing guidelines and standards.

ISO 45001:2018 OHSMS auditing helps organizations ensure the

effectiveness of their occupational health and safety management systems,

identify areas for improvement, and demonstrate compliance with the standard's

requirements. By conducting regular audits and addressing any non-conformities,

organizations can continually improve their OHSMS and provide a safe and

healthy work environment for their employees.

What are the clauses of ISO 45001:2018?

ISO 45001:2018, the international standard for Occupational

Health and Safety Management Systems (OHSMS), consists of several clauses that

outline the requirements for establishing, implementing, maintaining, and

continually improving an effective OHSMS. Here are the clauses of ISO

45001:2018:

- Scope:

This clause defines the scope of the standard and specifies the intended

outcomes of an OHSMS.

- Normative

References: This clause lists the references to other standards and

documents that are applicable to ISO 45001:2018.

- Terms

and Definitions: This clause provides definitions of key terms used in the

standard to ensure consistent understanding and interpretation.

- Context

of the Organization: This clause requires organizations to determine the

external and internal issues that may affect their OHSMS, as well as the

needs and expectations of interested parties.

- Leadership

and Worker Participation: This clause highlights the importance of

leadership commitment to the OHSMS and the involvement of workers in

decision-making processes.

- Planning:

This clause focuses on risk assessment, hazard identification, and

determining controls to manage occupational health and safety risks.

- Support:

This clause covers the requirements for resources, competence, awareness,

communication, documented information, and control of documented

information.

- Operation:

This clause addresses the implementation of controls and processes to

manage operations, including emergency preparedness and response.

- Performance

Evaluation: This clause outlines the requirements for monitoring, measuring,

analysis, evaluation, and internal audit of the OHSMS.

- Improvement:

This clause emphasizes the need for continual improvement, corrective

actions, and addressing non-conformities to enhance the effectiveness of

the OHSMS.

Annexes A to D: These annexes provide additional

information, guidance, and examples to support the implementation of ISO

45001:2018.

It's important to note that each clause contains specific

requirements that organizations need to fulfill to comply with the standard.

These requirements serve as a framework for developing and maintaining an

effective OHSMS, helping organizations prevent work-related injuries,

illnesses, and fatalities while promoting a safe and healthy work environment.

ISO 45001 Clause 4: Context of the organization

Clause 4 of ISO 45001:2018 focuses on the "Context of

the organization." This clause requires organizations to determine the

external and internal factors that can influence their Occupational Health and

Safety Management System (OHSMS). Here's a breakdown of the key aspects of

Clause 4:

- Understanding

the organization and its context: Organizations must identify the external

and internal issues that can impact their OHSMS. External issues can

include legal and regulatory requirements, societal expectations, market

conditions, and technological advancements. Internal issues refer to

factors within the organization, such as its size, structure, culture, and

values. By understanding these factors, organizations can effectively plan

and implement their OHSMS.

- Understanding

the needs and expectations of interested parties: Organizations should

identify the interested parties relevant to their OHSMS, including

workers, contractors, customers, suppliers, regulatory bodies, and

community members. It is essential to understand their needs,

expectations, and requirements related to occupational health and safety.

This knowledge helps organizations align their OHSMS with stakeholder

expectations and legal obligations.

- Determining

the scope of the OHSMS: Organizations need to define the boundaries and

applicability of their OHSMS. This involves determining which activities,

processes, locations, and workers are covered by the system. The scope

should consider the organization's context, interested parties, and the

nature of its operations.

- Management

commitment and accountability: Top management plays a crucial role in

demonstrating leadership, commitment, and accountability for the

effectiveness of the OHSMS. They are responsible for establishing the

context, providing the necessary resources, and ensuring that the OHSMS

aligns with the organization's strategic direction.

- Establishing

the OHSMS: Based on the understanding of the organization's context and

the needs of interested parties, organizations must establish their OHSMS.

This includes setting objectives, developing processes, and allocating

resources to manage occupational health and safety risks.

- Documented

information: Organizations should maintain documented information that

defines the scope of the OHSMS, its processes, and their interactions.

This information helps ensure consistency, transparency, and effective

communication within the organization.

By addressing Clause 4, organizations gain a clear

understanding of their internal and external environment, enabling them to

establish an OHSMS that aligns with their context and meets the needs of

interested parties. This proactive approach helps organizations effectively

manage occupational health and safety risks and improve their overall safety

performance.

Clause 4.1.1 of ISO 45001:2018 requires organizations to determine the external and internal issues that can impact their Occupational Health and Safety Management System (OHSMS). This process helps organizations gain a comprehensive understanding of the factors that can influence their ability to manage occupational health and safety effectively. Here's a closer look at this requirement:

- External

issues: Organizations must identify and evaluate the external factors that

can affect their OHSMS. These factors can include legal and regulatory

requirements, societal expectations, economic conditions, industry trends,

technological advancements, and changes in the organization's operating

environment. By considering these external issues, organizations can adapt

their OHSMS to comply with legal obligations, industry standards, and

stakeholder expectations.

- Internal

issues: Organizations need to identify and assess the internal factors

that can impact their OHSMS. These factors may include the organization's

structure, culture, values, resources, competencies, and governance. It is

crucial to understand how internal factors can influence the

implementation and effectiveness of the OHSMS. For example, the

availability of resources, management commitment, and employee engagement

can significantly impact the organization's ability to manage occupational

health and safety.

- Evaluation

of issues: Once the external and internal issues are identified,

organizations should evaluate their significance and potential impact on

the OHSMS. This evaluation helps prioritize the issues based on their

potential risks and opportunities. It enables organizations to focus their

resources and efforts on addressing the most critical issues and

proactively managing occupational health and safety risks.

- Documentation

and communication: Organizations should document the identified external

and internal issues as part of their OHSMS documentation. This

documentation ensures that the issues are well-documented, understood, and

communicated within the organization. It also facilitates effective

decision-making, planning, and risk management processes.

By determining the external and internal issues, organizations can proactively address the factors that may affect their OHSMS. This understanding enables them to develop strategies, allocate resources, and implement controls that effectively manage occupational health and safety risks. It also helps organizations stay informed about the changing external and internal landscape, ensuring their OHSMS remains relevant and adaptive to emerging challenges and opportunities.

4.2.1 Identify the other interested parties

Clause 4.2.1 of ISO 45001:2018 requires organizations to identify the "other interested parties" relevant to their Occupational Health and Safety Management System (OHSMS). This process helps organizations understand the needs, expectations, and requirements of these parties, enabling them to effectively manage occupational health and safety risks and meet stakeholder obligations. Here's a closer look at this requirement:

- Definition of interested parties: Interested parties refer to individuals or organizations that can affect, be affected by, or perceive themselves to be affected by the organization's OHSMS. Examples of interested parties can include workers, contractors, customers, suppliers, regulatory authorities, unions, shareholders, local communities, and other stakeholders with an interest in occupational health and safety.

- Identification

of interested parties: Organizations should systematically identify the

interested parties relevant to their OHSMS. This involves considering the

relationships and interactions between the organization and these parties.

It may require conducting stakeholder analysis, reviewing contractual

obligations, and seeking input from internal and external sources.

- Needs

and expectations: Once the interested parties are identified,

organizations need to determine their needs, expectations, and

requirements related to occupational health and safety. This can involve

gathering information through surveys, interviews, feedback mechanisms,

and relevant legal or regulatory requirements. Understanding the needs and

expectations of interested parties helps organizations tailor their OHSMS

to meet those requirements effectively.

- Incorporating

requirements into the OHSMS: Organizations should consider the identified

needs and expectations of interested parties when establishing,

implementing, and maintaining their OHSMS. This can include integrating

relevant requirements into policies, objectives, procedures, and risk

management processes. By aligning the OHSMS with stakeholder expectations,

organizations can enhance their overall performance and foster positive

relationships with interested parties.

- Communication

and engagement: Organizations should establish effective communication

channels to engage with interested parties and keep them informed about

the OHSMS performance, progress, and initiatives. This can involve regular

updates, consultations, feedback mechanisms, and involvement in

decision-making processes. Engaging with interested parties demonstrates

the organization's commitment to transparency, accountability, and

continuous improvement in occupational health and safety.

By identifying and understanding the needs and expectations

of interested parties, organizations can effectively manage occupational health

and safety risks, meet legal and regulatory obligations, and enhance their

overall performance. Engaging with interested parties fosters collaboration,

trust, and a proactive approach to managing occupational health and safety

within and outside the organization.

4.2.2 Clarify the needs and expectations

Clause 4.2.2 of ISO 45001:2018 requires organizations to

clarify the needs and expectations of interested parties related to their

Occupational Health and Safety Management System (OHSMS). This process helps

organizations gain a thorough understanding of the specific requirements and

desired outcomes of interested parties, enabling them to effectively address

occupational health and safety concerns. Here's a closer look at this

requirement:

- Determining

specific needs and expectations: Organizations should engage with

interested parties to clarify their specific needs and expectations

regarding occupational health and safety. This can be done through direct

communication, surveys, interviews, feedback mechanisms, and analysis of

relevant legal or regulatory requirements. The goal is to gather

comprehensive information on what interested parties require in terms of

occupational health and safety performance, controls, and initiatives.

- Documentation

of needs and expectations: Organizations should document the identified

needs and expectations of interested parties as part of their OHSMS

documentation. This documentation ensures that the requirements are

clearly defined, understood, and accessible to relevant personnel within

the organization. It serves as a reference for developing strategies,

setting objectives, and implementing controls to meet the identified needs

and expectations.

- Alignment

with organizational objectives: Once the needs and expectations of

interested parties are clarified, organizations should align them with

their overall organizational objectives. This ensures that the

occupational health and safety goals are integrated into the broader

strategic framework of the organization. Aligning the needs and

expectations with organizational objectives helps prioritize resources,

allocate responsibilities, and drive consistent improvement in

occupational health and safety performance.

- Planning

and implementation: Based on the clarified needs and expectations,

organizations should plan and implement measures to address occupational

health and safety concerns. This may involve developing policies, setting

objectives, establishing procedures, implementing controls, and allocating

resources. The aim is to ensure that the OHSMS effectively meets the

identified needs and expectations of interested parties and contributes to

a safe and healthy work environment.

- Continuous

monitoring and improvement: Organizations should continually monitor the

effectiveness of their OHSMS in meeting the needs and expectations of

interested parties. This involves regular performance evaluations, audits,

reviews, and feedback mechanisms. Any gaps or areas for improvement should

be identified and addressed through corrective actions and continual

improvement processes.

By clarifying the needs and expectations of interested

parties, organizations can develop and implement an OHSMS that effectively

addresses occupational health and safety concerns. This proactive approach

helps organizations enhance their overall performance, foster positive

relationships with stakeholders, and demonstrate a commitment to protecting the

health and well-being of workers and other interested parties.

4.2.3 Determine legal requirements

Clause 4.2.3 of ISO 45001:2018 requires organizations to determine the legal requirements and other requirements related to their Occupational Health and Safety Management System (OHSMS). This process ensures that organizations are aware of and comply with applicable laws, regulations, and other obligations pertaining to occupational health and safety. Here's a closer look at this requirement:

- Identification of legal requirements: Organizations should systematically identify and document the legal requirements relevant to their OHSMS. This includes local, national, and international laws, regulations, and legal obligations related to occupational health and safety. Examples of legal requirements may include workplace safety regulations, hazardous material handling requirements, emergency response protocols, worker protection laws, and reporting obligations.

- Determination

of other requirements: In addition to legal requirements, organizations

should also consider other requirements that are applicable to their

OHSMS. These can include industry standards, guidelines, codes of

practice, customer requirements, contractual obligations, and internal

policies and procedures. These other requirements may not have the force

of law but are important for ensuring effective occupational health and

safety management.

- Evaluation

of requirements: Once the legal and other requirements are identified,

organizations should evaluate their significance and applicability. This

involves assessing the potential impact of each requirement on the

organization's OHSMS and occupational health and safety performance. The

evaluation helps prioritize resources, determine the necessary controls

and measures, and ensure compliance with the most critical requirements.

- Documentation

and communication: Organizations should document the identified legal and

other requirements as part of their OHSMS documentation. This

documentation helps ensure that the requirements are clearly understood,

accessible, and communicated within the organization. It also serves as

evidence of compliance during audits and assessments.

- Compliance

and continual improvement: Organizations should establish processes and

controls to ensure compliance with the identified legal and other

requirements. This includes monitoring and reviewing the effectiveness of

controls, conducting regular audits, addressing non-compliance through

corrective actions, and implementing continual improvement initiatives.

Compliance with legal and other requirements demonstrates the

organization's commitment to meeting its obligations and protecting the

health and safety of workers.

By determining the legal and other requirements,

organizations can ensure that their OHSMS is aligned with applicable

regulations and standards. This proactive approach helps organizations maintain

legal compliance, mitigate occupational health and safety risks, and create a

safe and healthy work environment for their employees.

4.3 Determining the scope of the OH&S management system

Clause 4.3 of ISO 45001:2018 pertains to determining the

scope of the Occupational Health and Safety (OH&S) management system. This

step involves defining the boundaries and applicability of the OH&S

management system within the organization. Here's a closer look at this clause:

- Scope

definition: Organizations need to establish the scope of their OH&S

management system. This includes defining the boundaries of the system,

such as the locations, activities, processes, and functions that are

covered. The scope should be documented and communicated within the

organization to ensure clarity and understanding.

- Internal

and external factors: When determining the scope, organizations should

consider both internal and external factors. Internal factors may include

the organization's size, structure, nature of activities, and the type of

work performed. External factors can encompass legal requirements,

industry regulations, stakeholder expectations, and the needs of

interested parties. Considering these factors helps ensure that the scope

is comprehensive and aligned with the organization's context.

- Applicability:

Organizations should determine the applicability of the OH&S

management system. This involves identifying the hazards, risks, and

OH&S issues that are relevant to the organization's activities,

products, and services. By assessing the context and considering the

scope, organizations can identify the areas where the OH&S management

system needs to be implemented and applied.

- Exclusions:

In some cases, organizations may decide to exclude certain activities or

areas from the scope of their OH&S management system. However, such

exclusions should only be made if they do not affect the organization's

ability to achieve the intended outcomes of the system or result in the

neglect of OH&S responsibilities.

- Scope

statement: Once the scope is determined, organizations should develop a

clear and concise scope statement that describes the boundaries and

applicability of the OH&S management system. This statement should be

documented and communicated to relevant stakeholders to ensure a shared

understanding.

Determining the scope of the OH&S management system is

crucial as it defines the extent and focus of the system's implementation. It

helps organizations prioritize their efforts, allocate resources effectively,

and ensure that the OH&S management system addresses the relevant hazards

and risks within the organization. By establishing a well-defined scope,

organizations can establish a strong foundation for managing occupational

health and safety and achieving their OH&S objectives.

4.3.1 Take into account the external and internal issues

Clause 4.3.1 of ISO 45001:2018 emphasizes the importance of

taking into account the external and internal issues when determining the scope

of the Occupational Health and Safety (OH&S) management system. This

involves considering the factors and conditions that can influence the

organization's ability to achieve its intended outcomes and manage OH&S

risks effectively. Here's a closer look at this requirement:

- External

issues: Organizations should identify and evaluate the external factors

that can impact their OH&S management system. These factors may

include legal and regulatory requirements, industry standards,

technological advancements, economic conditions, societal expectations,

and emerging trends related to occupational health and safety.

Understanding these external issues helps organizations adapt and respond

to changes in their operating environment and ensure that the OH&S

management system remains effective and relevant.

- Internal

issues: Organizations should also consider the internal factors that can

influence their OH&S management system. This includes the

organization's culture, values, leadership commitment, resources,

capabilities, processes, and organizational structure. Assessing internal

issues helps organizations identify their strengths, weaknesses,

opportunities, and challenges in managing occupational health and safety.

It enables them to align the OH&S management system with the

organization's overall objectives and strategies.

- Analysis

and evaluation: Organizations should conduct a systematic analysis and

evaluation of the identified external and internal issues. This may

involve gathering data, conducting assessments, engaging with relevant

stakeholders, and seeking expert advice as necessary. The purpose is to

gain a comprehensive understanding of how these issues can affect the

organization's OH&S performance, its ability to prevent work-related

injuries and illnesses, and its overall OH&S management efforts.

- Integration

into the OH&S management system: The insights gained from analyzing

external and internal issues should be integrated into the design and

implementation of the OH&S management system. This includes

considering these issues when setting OH&S objectives, developing

policies and procedures, conducting risk assessments, implementing

controls, and monitoring performance. By addressing the external and

internal issues, organizations can enhance their ability to manage

OH&S risks and continually improve their occupational health and

safety performance.

By taking into account the external and internal issues,

organizations can ensure that their OH&S management system is aligned with

the broader context in which they operate. It enables them to identify and

respond to relevant risks and opportunities, engage stakeholders effectively,

and make informed decisions to protect the health and safety of workers.

Considering these issues helps organizations maintain a proactive approach to

managing occupational health and safety and adapt to the evolving needs and

expectations of their stakeholders.

4.3.2 Take into account the requirements of interested parties

Clause 4.3.2 of ISO 45001:2018 emphasizes the importance of

taking into account the requirements of interested parties when determining the

scope of the Occupational Health and Safety (OH&S) management system. This

involves identifying the needs and expectations of relevant stakeholders and

considering them in the design and implementation of the OH&S management

system. Here's a closer look at this requirement:

- Identify

interested parties: Organizations should identify the stakeholders who

have an interest in the organization's OH&S performance and outcomes.

This can include employees, contractors, suppliers, customers, regulatory

authorities, unions, local communities, and other relevant parties. By

identifying these interested parties, organizations can understand their

specific needs and expectations regarding occupational health and safety.

- Determine

requirements: Once the interested parties are identified, organizations

should determine their specific requirements related to OH&S. This

involves engaging with stakeholders through various channels, such as

surveys, interviews, consultation sessions, feedback mechanisms, and

reviewing relevant documentation. The aim is to gather information on what

these stakeholders expect in terms of occupational health and safety

performance, controls, communication, and participation.

- Analyze

and prioritize requirements: Organizations should analyze and evaluate the

requirements of interested parties to determine their significance and

relevance to the OH&S management system. This helps prioritize

resources and efforts to address the most critical requirements.

Organizations should also consider any legal or regulatory requirements

imposed by relevant stakeholders and ensure compliance with them.

- Integration

into the OH&S management system: The requirements of interested

parties should be integrated into the design and implementation of the

OH&S management system. This includes considering these requirements

when developing policies, setting objectives, establishing procedures,

implementing controls, and communicating with stakeholders. By addressing

the needs and expectations of interested parties, organizations can

enhance their overall occupational health and safety performance and

foster positive relationships with stakeholders.

- Continuous

monitoring and improvement: Organizations should continually monitor and

review the effectiveness of their OH&S management system in meeting

the requirements of interested parties. This involves seeking feedback,

conducting audits, performing performance evaluations, and engaging in

regular communication with stakeholders. Any gaps or areas for improvement

should be identified and addressed through corrective actions and

continual improvement processes.